Condenser Design Calculation Pdf To Jpg

Condenser Design Calculation Pdf To Jpg Converter

. CFM of compressed air required to raise a known system pressureto a desired system pressure: C2 = Required CFM totalC1 = Existing or known CFMP2 = Desired pressureP1 = Known Pressure EXAMPLE: A 75 HP Compressor rated at 320 CFM t 125 PSIG will hold only 85 PSI and we desire 125 PSI. C1 = 320 CFMP2 = 125 + 14.7 (139.7)P1 = 85 + 14.7 (99.7)C2 = 448.39 Total CFM requiredWe need an additional 128.39 CFM to raise system pressure to the desired level.

Simple Energy Formula: Motor Efficiency = Cost per KW X.746 (Power Factor) X Hours of operation X Brake horsepower.Note: No electric motor is 100% efficient, most will average 92-95% efficient. PSI VS. BHP (Rule of thumb): For every 1 PSIG pressure drop, BHP (Brake horsepower) goes down ½%.

Starry night college version 7. P2P group has released the newest build of “WondershareAllMyTube” for windows. EnjoyDescription: Starry Night Pro Plus 8 has been retooled from the inside out to best meet the needs of the modern amateur astronomer!

. 398 DownloadsPart of thebook series (EUROTHERM, volume 18) SummarySteam surface condenser is an important component in a power plant. It condenses the latent heat of the turbine exhaust steam. Therefore, the turbine efficiency is directly influenced by the performance of the steam surface condenser.

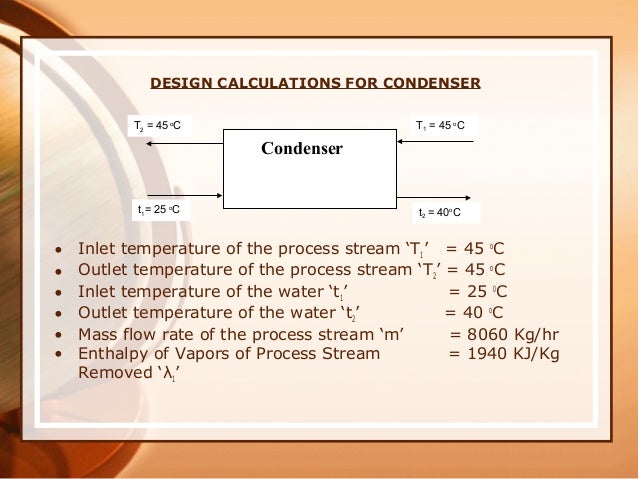

This work is to develop a computer-aided condenser design software, written in Quick Basica language. This software can be run in a personal computer(PC/XT, PC/AT). The design methodology is based a method proposed by Heat Exchange Institute for Steam Surface Condensers1.

This program has the following four functions: (1)Rating the condenser (2)Sizing the condenser (3) Calculating the cleanliness factor and (4) Determining the condenser absolute pressure. The features of this program are powerful interactive ability and high accuracy.

Calculation results are available within seconds. The program has been checked against controlled performance test and operating data on installed steam surface condensers.